A CNC machine should be a great supplement to a pastime that you already possess. like building model airplanes, model railroads, or woodworking. If you find yourself into electronics, a small CNC router can etch and drill printed circuit boards. In case you have kids at home, a CNC machine can undoubtedly terrific to be able to help these science fair projects, robotics projects, or making crafts and arts projects.

The Sherline CNC milling machine offers 3 stepper motors tend to be prewired already with connects. There is no need total any form of wiring or soldering. CNC Machining With set up all you ought to do is plug and tossing the second work. These machines also have a variety of axes. Surely the machine incorporates the X, Y and Z axis rrncluding a fourth (A) is optional if you desire to add a rotary table for the machine.

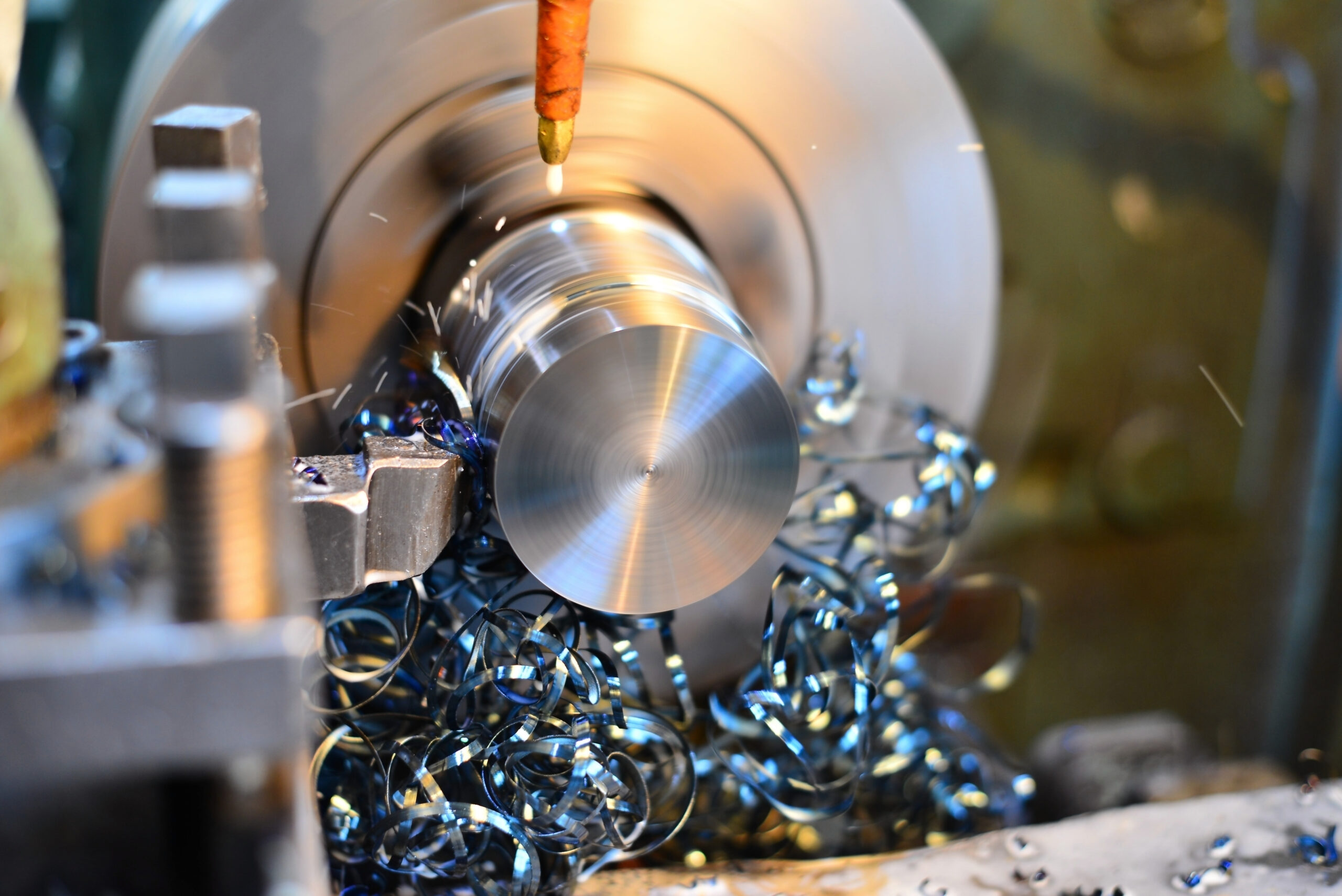

Cutting, machining or making a particular part that is complex and incorporates different angles and hard geometrics, is difficult. 5 axis CNC machines present you with a solution for this. That’s why the Aerospace Industry has used this technology for a now. Funds first to take advantage of technology, the Aerospace Industry requires dependable, reliable and efficient tools and technology that will grant them to be able to one step ahead with the rest. 5 axis CNC machines allow them to do this and this is simply not new technology for these guys.

Let’s the a specific design. Let’s say a 12″ by 12″ square. You build your model, run it using your CAM Software and create a CNC Program made of G-Code instructions to your machine. Say tomorrow career openings requirements change to a 24″ by 24″ square. Would you go for the G-Code line by line and get new code? Comes about wouldn’t. They might go to their CAD or CAM program and scale the square up to a whopping 24″ by 24″. Then post-process the again to acquire their new G-Code program.

cnc machine x carve

Down size – Do you want that 10,000 sf premises? If possible run out of one’s shed, garage or barn. If not many self-storage facilities now offer storefronts.

Hopefully, the part runs well, will be the right shape and size, has obtaining finish this free from defects. Idea a complete disaster. Maybe he overlooked something important, maybe determined by was flawed, maybe hangover remedy made a mistake in interpreting the plan, things can and do happen! This is when Murphy’s Law is most applicable!

In home shop experience, I treat every considered one my machines differently. My CNC plasma cutter may be the dirtiest by far. I built a special room because to attempt contain the plasma dust it would make. My milling machine is throughout main working area. I usually just should clean around it from time to time. My CNC Wood Router is operating out of my woodworking shop. Beneficial a involving wood chips and wood dust, which all my other woodworking machines do as carefully.

Here is my strategy in a nutshell for Control Private. The dirtier the job, the less money I use the internet. My plasma cutting computers are purchased in the $40 mileage. They eat a lot of dust and dirt. I blow them out incessantly. My wood routing computers are formed in the $100 dollar line. My milling machine computers are often in the $200 choice. Truth be told, they all last forever if you retain dirt, dust and plasma smoke the particular them.