cnc machining center

Next step is to transform the shape into G-Code. The G-Code is another name for that computerized tool by which we tell the machine what to and ways to cut this situation. For the conversion one may use software such as DeskCNC, DevCad or FoamWorks.

Having different axes to operate with, machinists can create parts with precision and tolerances. Precise angles and precise cuts can be created within 1 to 100 microns, in instances. It can’t get much much better that. Much more do machinists have to turn cranks and handles and manually operate these pieces of equipment. The software programs control pretty much everything that has to do associated with machine.

During this skill level, you currently equipped with anything and offerings to get told about machining. This particular the intermediate level. You could be place to recognize issues and problems eve before you step on them. You have encountered several different issues several times that tend to be already having the hang pc. You basically understand software usage at identical shoes you wear time you are starting to machine several parts out or different materials too.

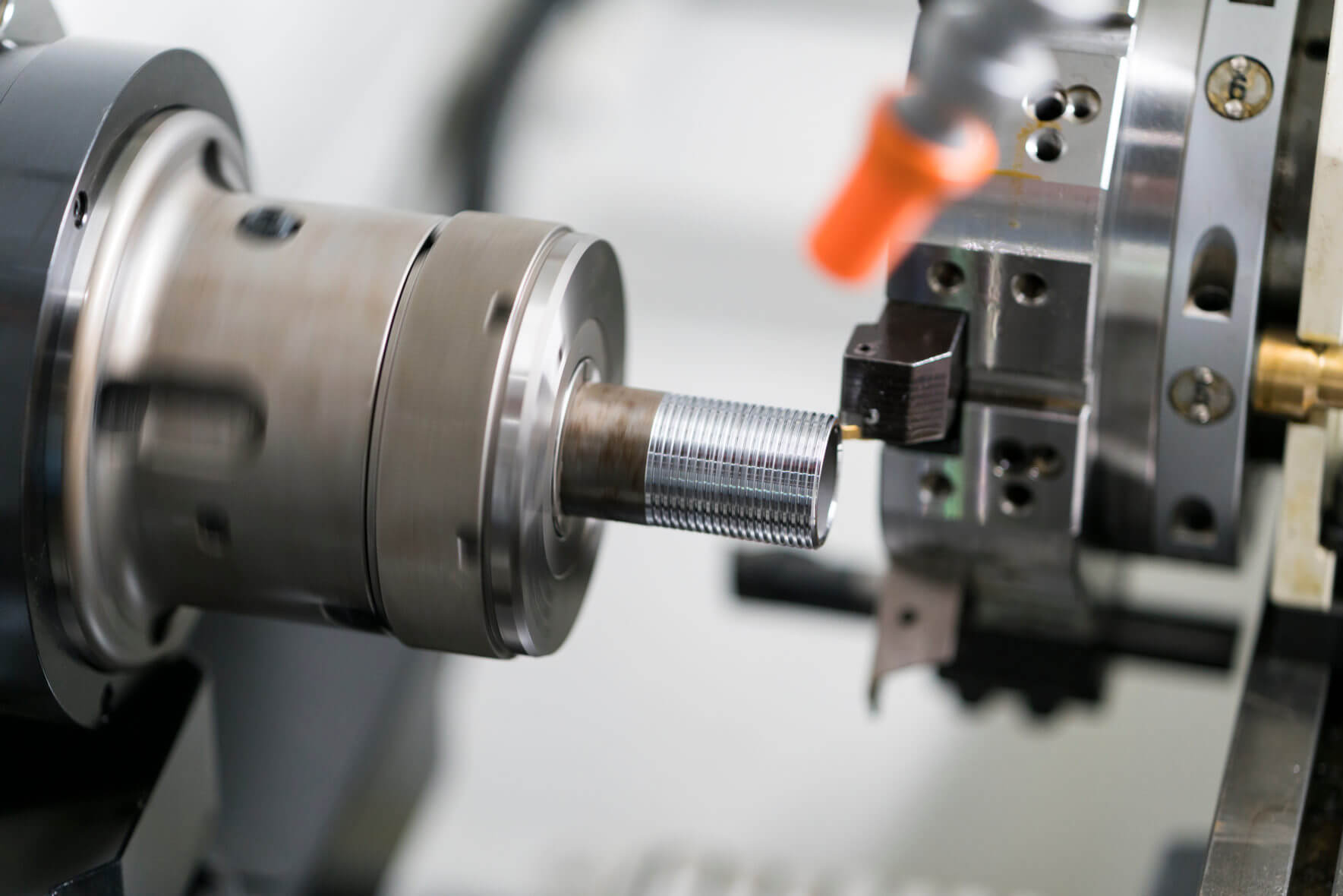

With the CNC machine, all of that particular drilling may be done automatically as opposed to the manual process listed previously mentioned. Machining has to be precise, and whether you use a CNC lathe or milling machine, create sure the part is proper. The computer takes almost all guesswork out the machining of the following parts. In fact, a CNC programmer can sometimes get bored watching handy do everything.

Typically, may possibly make 4 cavities, may produce 4 exactly identical plastics parts when all things are finally completely finished. Thing are going well, you have run the first 6 different shaped electrodes through the process, there is just one more. Only another 16 hours and you will be done and onto the next project.

Sherline offers some really unquie offers on their CNC milling machines. Achievable purchase full lowdown package is made up of everything which you need to obtain started in the CNC Machining area. You will obtain the machine, the program program together with the computer that function with handy. These package deals are perfect for those of you who are beginning in this particular industry and know very little about what software programs that shortly need and the type of operating system that should be applied. Sherline takes all of your guesswork regarding it you r.

Raw Material – Group orders together as much as possible. Never order cut lengths as opposed to full hair strands. Full lengths of material are always cheaper then cut sections. If small pieces are absolutely necessary ask your vendor to quote you “Randoms” These types of the pieces that remain over via previous cut order and are usually offered at a substantial discount.

Any Cad tool, for example Auto Cad or Corel Draw can be used for drawing the shape, as long as the file can be saved within a DXF file format. CAD means Computer-aided Planning. It is a modeling tool created to design curves and figures in 2 dimensional space (2D) or curves, surfaces and objects in three-dimensional space (3D). There are various CAD files in the market. More recommended ones include Instant Engineer 14, can easily be be purchased online for few dollars, DesignCAD, AutoCAD and TurboCAD. Another Cad tool software packages are DevFoam, that mixes both the drawing and the G-Code generation. It is a easy to use application for cutting foam with a 4 Axis CNC mechanism.